Success stories

Get inspired by others

Whether you like a challenge or simply must deal with them from time to time, you can always use some good advice to get you started.

Read about which kind of results that could be achieved with the Rindex System.

Make money on jaws and cutting tools

As a part of an efficiency enhencing project, the Rindex System was used when producing thin walled details in 2019.

The goals were was shorter set-up time and a higher production rate without clampingmarks.

During 2019, a quality improvement project took place at LK Precision Parts in Stockholm. The goals were easy to formulate, but more difficult to achieve:

“to make rounder parts quicker and with better surface finish.”

TPA Engineering planed the project,

MPC assisted with Quick-change jaws and revolutionary counterweights. Sandvik Coromant chose their best cutting solution given the low initial clamping force and high spindle speed made possible by the counterweights.

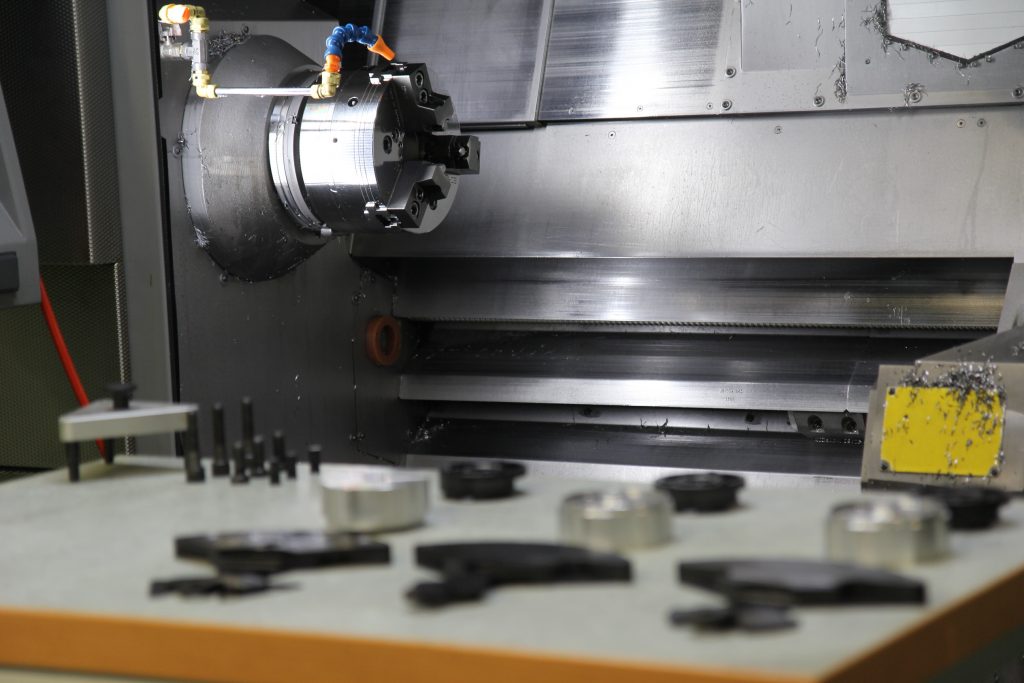

The test was made in real production. A round, thin-walled part in steel (1914) with diameter

Ø 88 mm and Ø 55 mm produced in a Nakamura equipped with a Kitagawa 210 chuck.

The Rindex system was mounted in the primary spindle and conventional turning set-up mounted in the sub spindle. Thus, we were able to compare results.

The customer needed 30 parts quick, why LK manufactured them part by part. The sub-sequent 350 parts were delivered at a later time.

• Set O.D. In our case Tempo 1 = 0.089 m, T2 = lowest possible torque

• Set friction coefficient (0.5 = steel to aluminum, 0.75 for aluminum to aluminum).

• If you have a “trail of strength” machine, use it to evaluate the accurate torque curve as speed increases (with and without counterweights).

• Without ”trail of strength” machine, use our estimations and add some safety margin. Then, use the ”trial and error” method to find optimal clamping force for your part.

• The jaws can now be prepared for Tempo 1 and Tempo 2

The parts did meet the required specifications (roundness) 50 µm as 20 µm was achieved on the

first try.

Conventional turning could not meet the requirements as 60-80 µm was possible. No parts needed to be reworked or thrown away.

Conventional manufacturing did leave clamping marks on some parts, which is a big issue for most customers, resulting in sub sequent grinding. No clamping marks were visible when using large clamping surface jaws and counterweights.

The latest cutting tool technology have made significant impact on metal removal rate. For

small to medium size parts, high spindle speed is often a better alternative to increase metal removal rate than feed and dept.

With higher demand on surface finish, regardless of functionality, spindle speed limitations will leave customers dissatisfied. With highest possible RPM and lowest possible clamping force, there will be less disposal and grinding.

Parts were manufactured 2-3 times faster compared with traditional turning. According to Sandvik Coromant, increased machining with 50 % is equal to a 25 % increase in gross margin. This means we managed to increase gross margin by 100-150 % as well as lower the component cost with 50-

80%, just by turning faster.

Add 100 % extra machine time as no measuring and rework was needed, we end up with a combined gross profit estimate of 150 – 200 % from the counterweights only.

As you can turn the quick-change jaws in less than a minute without reboring them, you will save roughly 20- 30 minutes every time you want to change diameter.

Testing the rindex system

Lessons learned when operation with the Rindex System

How Rindex works for you

Optimization made easy

Learn how Rindex helps you to optimize cutting data.Read why spindle speed is key to optimization

Need more details? Contact us

We are here to assist. Contact us by phone, email or via our Social Media channels!